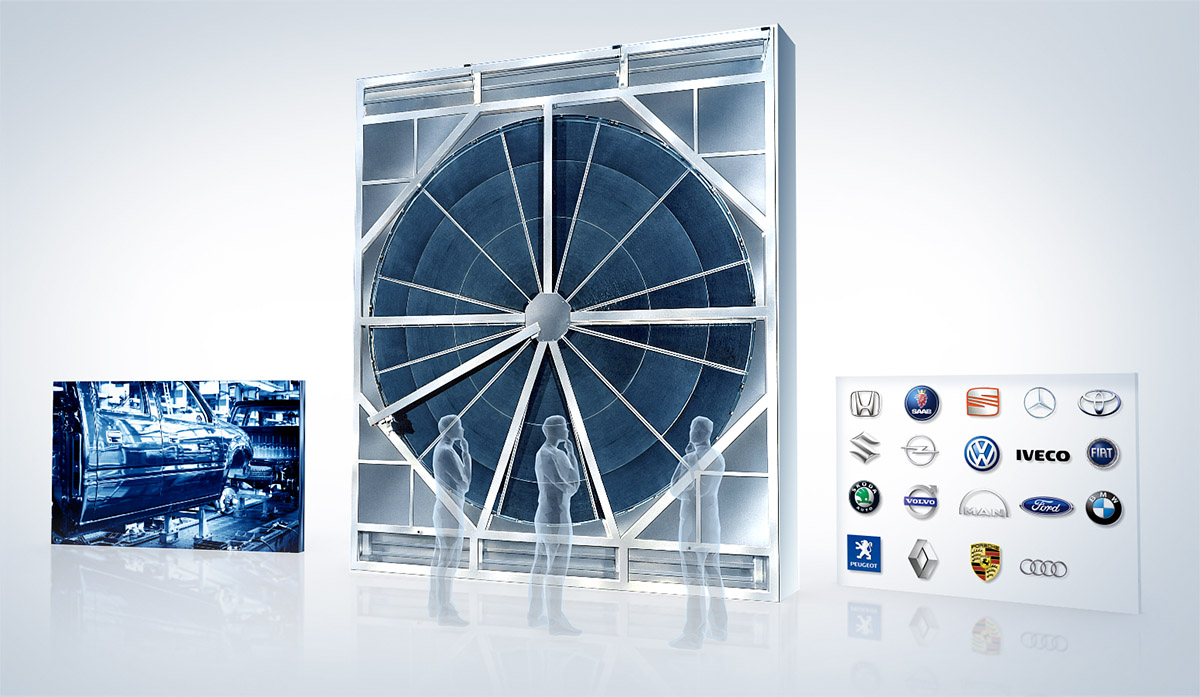

All major automotive brands rely on Klingenburg paint rotors. These units offer exceptionally high viability and fast payback periods. The rotor recovers the majority of the process energy and resupplies it for the process.

It also captures the majority of the paint particles in the air, thus functioning as a filter. A tried and tested cleaning system keeps the rotor clean despite the significant paint particle contamination of the air.

The following manufacturers use Klingenburg paint rotors in their paint shops:

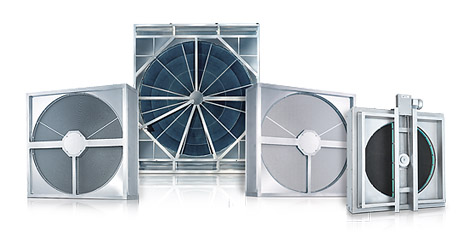

Custom Versions

We supply paint rotors individually adapted to the technical requirements of your plant. This means you can obtain Klingenburg storage masses and housings precisely fitted to your plant - in a choice of stainless steel, aluminium or galvanised steel.

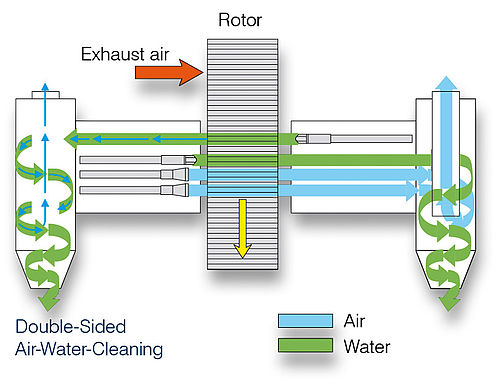

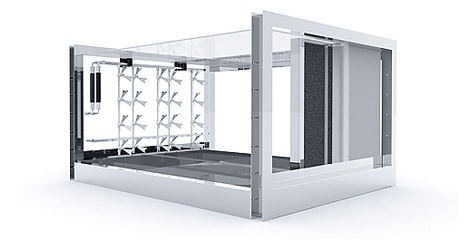

High-Efficiency Cleaning System

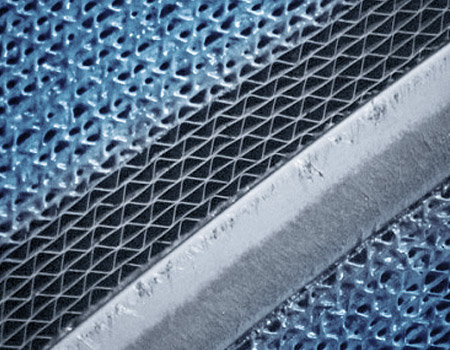

Paint rotors are subject to exceptionally high levels of contamination, which can make cleaning them a real challenge. The storage mass has to be free of all tough paint particles and highly corrosive compounds.

In particularly stubborn cases we administer double-sided air and water cleaning.