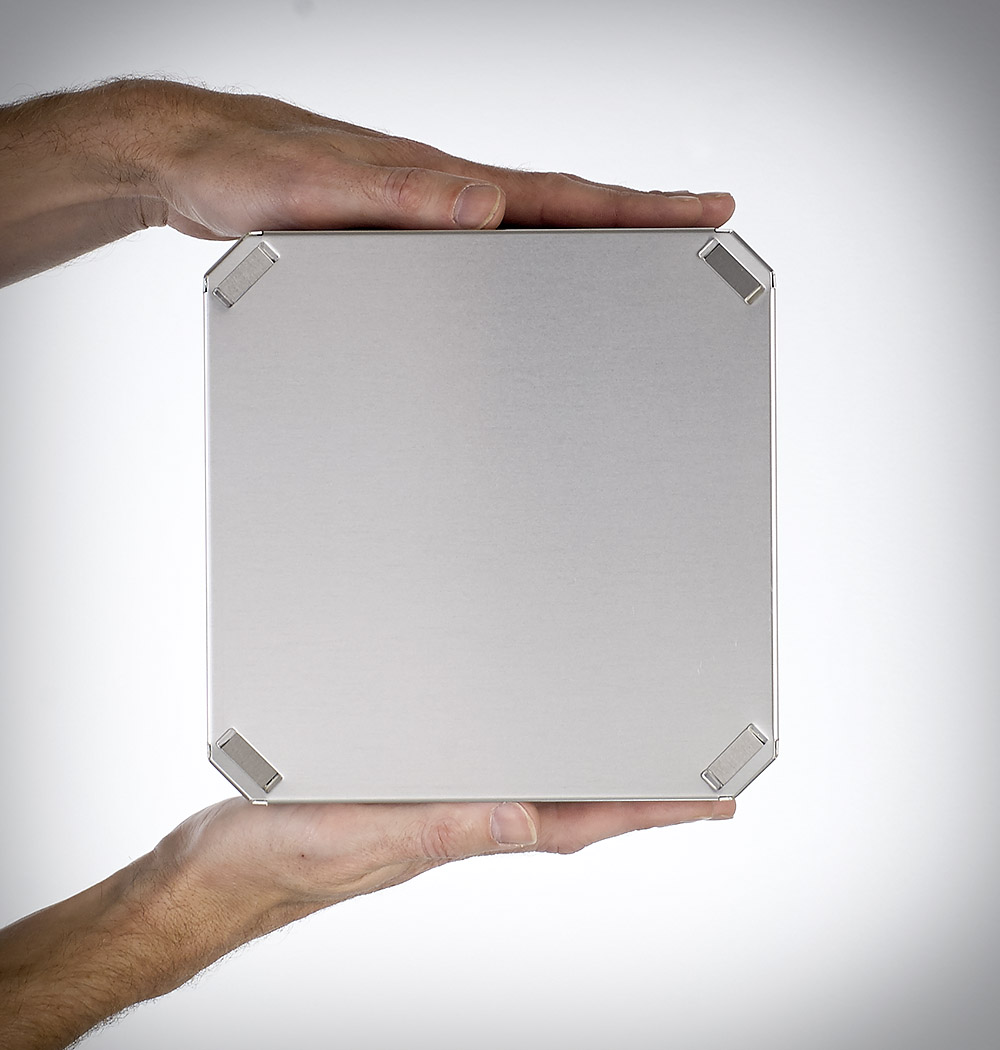

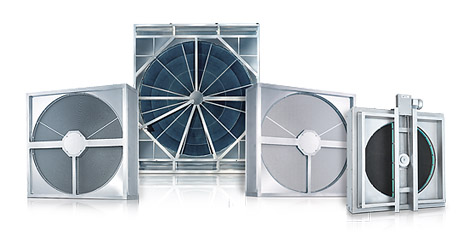

The cross-flow plate heat exchangers (PWT) from Klingenburg are dimensionally stable and exceptionally impermeable and tough. Available in aluminium, epoxy-coated aluminium or stainless steel as required.

Ideal for use in industry, in ventilation and extraction systems, for adiabatic cooling and for cooling electrical cabinets.

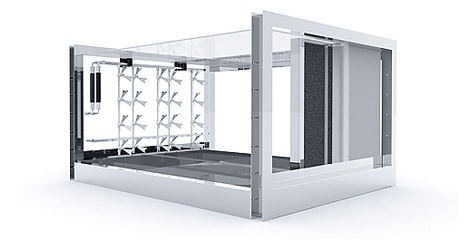

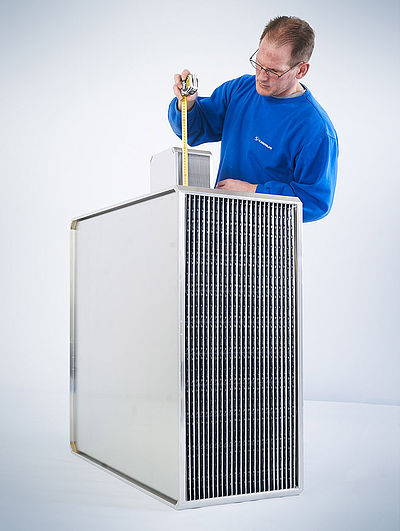

Our cross-flow exchangers are available as individual units with edge lengths from just 200 to 1200 millimetres. Combined as modules, there is practically no limit.

Suitable for air temperatures up to 300°C, important in the textile and film industries, detergent and PVC production and sewage-sludge drying.

Exceptionally Stable and Impermeable

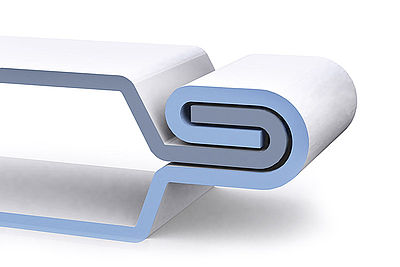

Plate exchangers are often built into systems in which air circulation is unwanted. The internal and external air flows must therefore be completely separated.

Even the slightest gaps or nooks have to be eliminated. Maximum impermeability is thus called for – and our plate heat exchangers deliver.

Larger models with edge lengths of 500 mm or more and potentially exposed to particularly high pressures are double-folded at the inflow edges, which gives them exceptional sealing.

The double fold gives the edges five times the strength of the construction material, lending the plate exchanger outstanding stability, however high the air pressure.

Exceptionally Hygienic

Klingenburg plate exchangers also feature a uniquely hygienic design. Our special sealant has an adhesive effect that blocks off all possible nooks, niches or gaps that could be colonised by bacteria.

Consequently all condensate flows out of the exchanger, leaving no residue whatsoever.

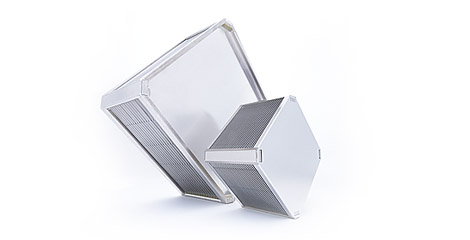

Withstands the Highest Temperatures

Particularly in industrial applications such as process air systems, cross-flow plate heat exchangers must often withstand extreme temperatures. Airflows at temperatures of up to 300°C are no problem for our stainless steel models.

We offer various module variations to meet your requirements, together with installation-ready housings.

Example Applications for High-Temperature PWT's

Exhaust air from

drying conveyors

- Sewage sludge drying

- Coating industry

- Textile industry

- Film industry

Exhaust air from

spray dryers

- Washing powder manufacture

- PVC production