Anybody wishing to heat a single room or indeed a whole building requires significant heat energy. Moreover, anyone wishing to cool a room in a warm or humid region of the world will expend still more energy.

However, intelligent technology lets you recover up to 90% of this energy and use it to make savings. All thanks to the action of heat exchangers. These units can function on different principles, such as those of regeneration and recuperation.

Air-to-Air Heat Exchangers

In energy recovery - often referred to simply as heat recovery - the warmth (or coolness) of an indoor space is made reusable. Heat and cold are different designations of thermal energy.

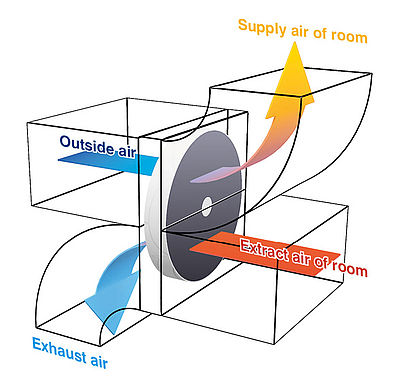

Let us assume that your building is equipped with a ventilation and extraction system. This means you have two active and separate airflows. One draws outside air into the building (supply air), while the other draws room air outside (exhaust air).

A distinction is made between winter and summer operation. In winter the exhaust air channel carries air that is used but also warm air out of the building. Fresh new air enters via the supply air channel.

In summer the reverse occurs: now cooled but used air flows out via a cooling unit. The supply air is warm but unused.

You can exploit the differences of temperature and moistness to recover room warmth or coolness depending on the season.

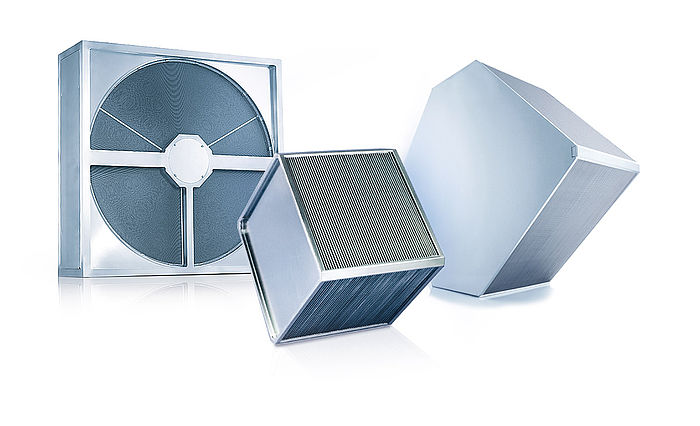

Rotation and Plate Heat Exchangers

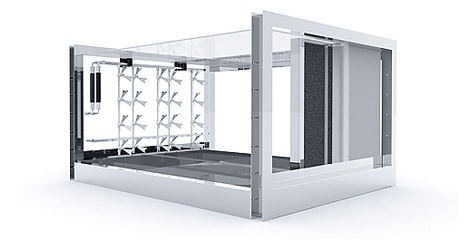

Heat exchangers come into use at the interface between the airflows. The heat exchanger transfers the majority of the thermal energy from the exhaust air to the supply air.

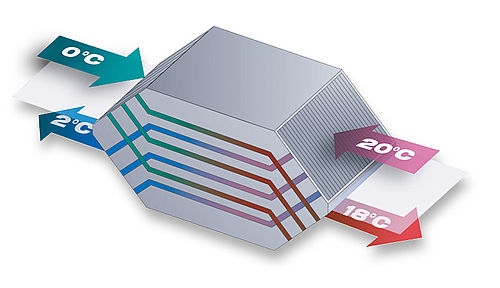

In winter the cool supply air is warmed, while in summer warm supply air is cooled. The heat or cold is thus recovered from the exhaust air. The thermal energy conductors used are generally foils or plates made of aluminium or special plastic.

Klingenburg manufactures plate heat exchangers and rotary heat exchangers for energy recovery from all room sizes and for all applications, from a one-room flat to a manufacturing hall, from hospitals to data processing centres to cruise ships.

Plate heat exchangers operate on the principle of recuperation, while rotary heat exchangers use the regeneration principle.

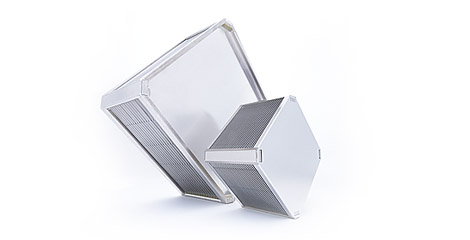

Plate Heat Exchangers: Recuperation

In a plate heat exchanger, in our example a Counterflow plate heat exchanger, thin plates of aluminium or plastic are stacked within the device. Indents in the plates provide gaps through which the supply and exhaust air flows.

Each gap containing supply air is adjacent to one containing exhaust air. so that the thermal energy traverses the plates from one airflow to the other. This occurs on the recuperation principle.

In recuperative systems there is no mixing of supply and exhaust airflows. which makes plate-type heat exchangers suitable for buildings in which maximum purity and hygiene are required, e.g. hospitals. These units are available as either Counterflow or Cross-flow plate heat exchangers.

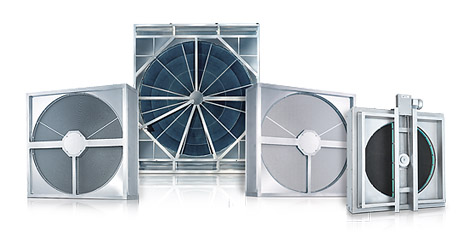

Rotary Heat Exchangers: Regeneration

A rotary heat exchanger operates on the principle of regeneration. Here, a honeycomb-like storage mass in aluminium provides axial channels through which the supply and exhaust air flows. After a half-rotation of the heat wheel, the aluminium foil collects and transfers the thermal energy of the exhaust air to the supply airstream.

Unlike plate heat exchangers, in this system the two airstreams are not hermetically isolated. Since the temperature of the aluminium storage mass is constantly changing, this process is described as regenerative heat recovery.

Rotary heat exchangers can be up to eight metres in diameter. They process very large air volumes, making them ideal for large buildings such as factories and office complexes.

In contrast to plate heat exchangers they also have the advantage of transferring humidity as well as sensible heat.