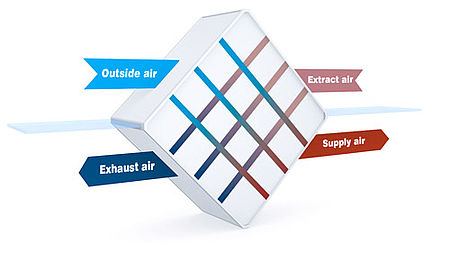

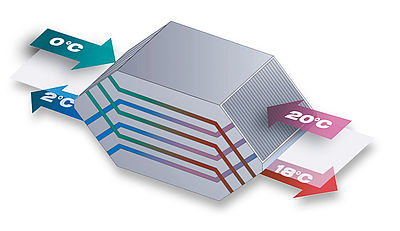

Plate heat exchangers are the preferred option in ventilation systems where any ‘circulation’ of air is undesirable. In other words, the incoming and outgoing airstreams are completely isolated and no moisture or odours can be transferred. Thus, plate heat exchangers are examples of recuperative energy recovery systems. As with rotary heat exchangers, plate exchangers recover heat energy in winter and coolness in summer.

A distinction is made between two different types of plate heat exchanger: Counterflow and cross-flow designs.

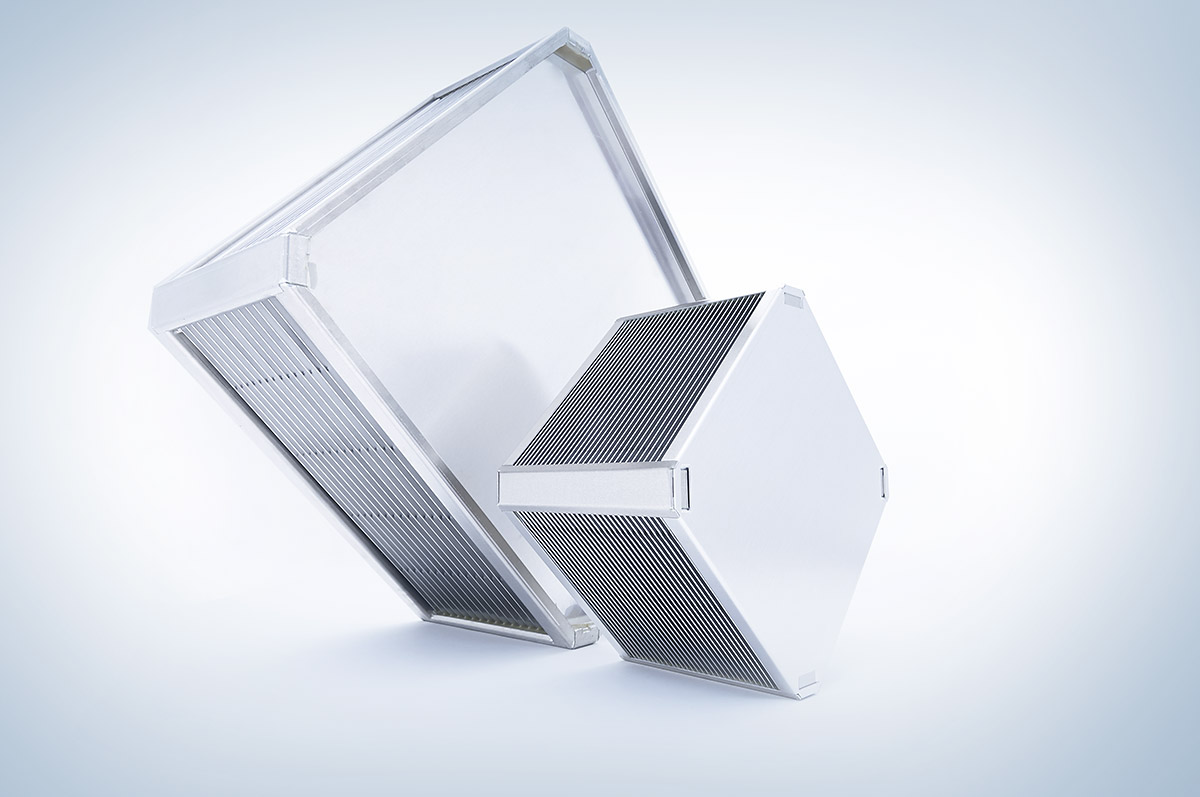

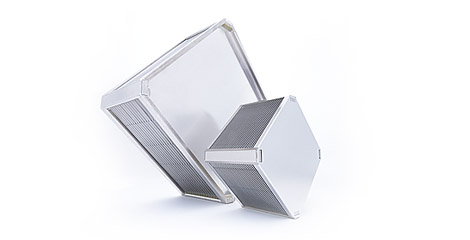

Counterflow Plate Heat Exchangers

These designs achieve energy recovery efficiencies of up to 90%. Counterflow heat exchangers are primarily used in ventilation and air-conditioning systems and particularly suitable for controlled ventilation of living spaces.

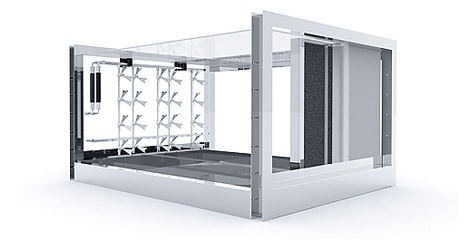

At the core is a stack of aluminium or plastic plates, within which recesses create airflow channels. In Counterflow units the channels are arranged to ensure precisely opposing airflows and thus maximize the heat energy exchange. In winter the highly heat-conductive plates transfer heat from the exhaust airstream to the supply airstream. The reverse occurs in summer, when the warmer entering air is cooled.

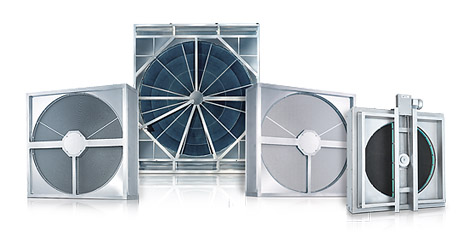

Cross-Flow Plate Heat Exchangers

Cross-flow plate heat exchangers are also increasingly seen in industrial ventilation and extraction systems. These designs can be substantially larger in size than Counterflow units.